Over the many years that Meridian Medical has been operating, we have learnt some valuable lessons when it comes to designing medical devices, from the initial concept and prototyping through to full-scale production. We believe that understanding some of the key elements in this process can help would-be and existing designers of disposable and single-use medical devices.

Here is our guide to the key considerations when designing a medical device:

- Components and materials

The first stage in designing a medical device is the concept itself, but then comes the practicality. The concept of ‘marginal gain’ revolutionised British cycling’, with the smallest details challenged and honed to perfect the overall performance of the athletes.Choosing parts and materials wisely could help you create a medical device that works better, simplifies production, reduces manufacturing, delivery and disposal costs. - The end user

Even the best designs can fail if the way in which a medical professional will or needs to use the device isn’t taken into account. How the device will be stored, the speed that a medical professional may need to access or employ the device and the comfort of the patient are all crucial considerations. By considering both the user, and the patient, at the design stage will increase the likely success of your medical device. - Prototyping

Creating a draft version of your medical device enables you to explore your idea, refine the concept or process, before going into full production. Medical product prototyping using 3D printing for the designs and injection mould tools specifically created for short sample runs will allow you to refine your concept or design and again, increase the likely take-up of your product by medical organisations. - Sterilisation

Regulations determine the sterile state in which your product should arrive with the end user. The extent and method of sterilisation will be determined by the purpose of your device and the materials that have been used to manufacture it.By working with an experienced contract manufacturer of medical devices and one that offers an end-to-end service, you can be assured of access to extensive cleanroom facilities and certified sterilisation processes suitable for your product, as well as full management of the sterilisation process. - Packaging

While the design of the medical device itself could be uppermost in your mind, the packaging in which it will be stored also needs consideration. Packaging must maintain the sterility of the device, but the device itself needs to be easily accessed, potentially in an emergency.The nature and purpose of your medical device, as well as its sterilisation and storage requirements, will determine the type of packaging required. Whether you choose a traditional peel pouch or blister style tray packaging, there are lead time considerations to be taken into account. Pouch packaging can have a shorter lead time, as well as a lower cost, whereas blister packs can look more professional but require additional tooling and typically have a higher unit cost. The end user of your device may never see the product in its packaging, so packaging cost and function are important.Packaging must also go through a validation process, to be checked for shelf-life, integrity and the level of sterility assurance.

Meridian Medical is an established and experienced contract medical equipment manufacturer, specialising in a wide range of medical device design, development and supply services.

To find out more about how Meridian Medical can help you with your medical product design and manufacture, get in touch today by filling out our online form, calling us on 01903 732344 or emailing info@meridian-medical.com.

Author: Paul Kearsley,

Technical Manager, Meridian Medical

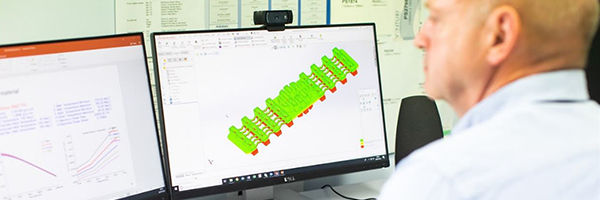

Paul Kearsley brings a lifetime of engineering expertise to his role as Technical Manager at Meridian Medical. With an HNC in Mechanical Engineering and a foundation built during a four-year engineering apprenticeship, Paul has spent over 40 years running his own design company. Over the decades, he has designed more than 1,000 consumer, industrial, and medical devices, showcasing his ability to deliver innovative solutions across a broad spectrum of industries.

A pioneer in the transition from traditional drafting techniques to modern CAD workflows, Paul began his career on the drawing board, adopted AutoCAD 2D early on, and embraced 3D modelling with SolidWorks in 1997. His vast experience and technical leadership play a key role in Meridian Medical’s commitment to producing high-quality, single-use medical devices.