The need to manage infection risks and prevent cross-contamination in medical institutions requires stringent processes for the cleaning and reuse of equipment, all of which takes time, resources and often costly specialist equipment. This can add costs to budgets already under pressure.

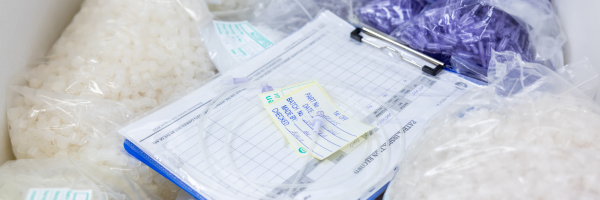

Disposable medical devices and single-use devices, on the other hand, often present both a time and cost saving opportunity for medical centres. These medical and surgical devices are manufactured to support diagnosis and treatment. They are objects used by the medic only once, or temporarily for up to as much as 30 days.

The medic can be confident that the equipment is sterile each time because it is new, while the materials used need not be so expensive because the device is not required to be used more than once.

Medical disposables came about because they are often cheaper and more efficient to produce and use, while reducing the risk of infection and cross-contamination to patients.

What products are considered to be medical disposables?

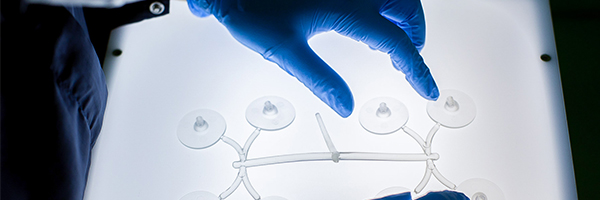

An obvious example of a medical disposable is a speculum, which when made of metal is re-usable but would also require extensive processing to clean and sterilise for re-use. There is also a higher risk of infection and cross-contamination, as the cleaning and sterilisation process may be inadequate. Alternatively, a disposable speculum, made of plastic, which is clean because it is new, would work out cheaper on the basis of per patient use.

There are many other such examples – the single-use anoscope, retractor, laryngoscope, urinary catheter, the face mask for oxygen administration, feeding syringes, nebulisers and inhalers among them.

Manufacturing disposable medical devices

Medical device manufacturers worldwide produce many types of disposable devices but cost is not always the primary factor when it comes to their design. The design of single-use medical devices must balance performance, reliability, materials and shelf life, as well as cost.

Working with a contract manufacturer of medical devices provides access to all the services you need, including design, testing, storage and logistics, to bring your disposable medical device to market.

Meridian Medical is an established and experienced contract medical equipment manufacturer, specialising in a wide range of medical device design, development and supply services.

To find out more about how Meridian Medical can help you with your medical product design and manufacture, get in touch today by filling out our online form, calling us on 01903 732344 or emailing info@meridian-medical.com.

Author: James Fenton, Managing Director

James Fenton, Managing Director of Meridian Medical since 2017, has over 20 years of industry experience. He has been pivotal in developing and producing over 500 types of single-use medical devices, including CE-marked class 2 and 3 devices. With a strong focus on business strategy, project management and customer support, James ensures Meridian Medical's agility and innovation. His expertise is backed by qualifications in Business Studies and Medical Process and Equipment Validation, plus extensive industry training. James's insights into the industry that he has dedicated his entire career to provide a bank of invaluable information aimed at increasing knowledge of and driving advancements in medical device manufacturing.