The expiry, or near expiry, of the shelf life of a medical device can be a problem for medical device manufacturers when your device is low volume with a large minimum order quantity (MOQ) or sales have not been as forecast.

This situation can have a direct impact on a company’s sales and market profile, as all devices must undergo shelf-life testing and can’t be sold on the market without it. There are also wider cost implications. It is therefore important to make the right decision when a device’s shelf-life expires or is close to expiry.

Why significant shelf life is important and why expiry happens

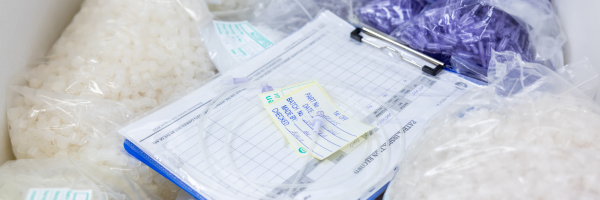

Medical device shelf-life testing is carried out in accordance with BS EN ISO 11607-1:2020 and must conform to the criteria set out in this guidance. This standard gives guidance on what type of materials should be used and how they are tested. Further guidance for accelerated aging can be found in ASTM F1980.

One of the key criteria that defines the shelf life of a medical device is how long the product packaging can keep a product clean and/or sterile.

Medical device manufacturers and end users want to receive medical devices with a significant shelf life. This gives them a sufficient period of time to sell or use them before that shelf life expires and the products can no longer be used.

Manufacturers are often faced with having medical devices with limited shelf life in stock. This can happen for a number of reasons. For example, a product can start out as a slow mover then a large order for it is received, or the product can be new with little or no traction in the market.

What to do when medical device shelf-life expiry is an issue

When the shelf life of your medical device has expired or has only a small amount of validity remaining, you have three options:

Option 1: Dispose of the product and manufacture it again.

Option 2: Use the initial shelf-life testing data to repack, using for example medical pouch packaging, and re-sterilise the product to extend the shelf life.

Option 3: If it has multiple parts, remove the part with the lowest shelf life and replace it, giving the product new packaging, labels and so forth.

In general, it is more cost-efficient to choose options 2 or 3 and rework the device. These options keep the product on the market and generating sales. It is also more environmentally friendly to do this as you avoid sending devices to landfill. However, reworking is not possible for all products; for some, disposal is the only option.

With regard to option 2, a common strategy used by manufacturers is to purposely give a medical device a reduced shelf life. For example, when a device receives a five-year shelf life, a manufacturer can choose to give the product only a three-year term, giving them the option (and flexibility) of two extra years.

The benefits of outsourcing medical device shelf-life testing

The outsourcing of medical device shelf-life testing has a range of benefits, in terms of both cost-efficiency and product performance. These advantages naturally apply to times when product shelf life has expired or is limited.

If you use a contract medical device manufacturer, it is always better that they also carry out any shelf-life testing-related rework. They will be able to use the same materials, equipment and facilities, which will help ensure that the rework can be carried out as quickly and efficiently as possible, particularly when it comes to validation.

Your outsourcing partner will hold lots of products and packaging and have your device’s shelf-life validation data, further ensuring a straightforward and expedited service. They will also be able to provide advice on process and product suitability, guide rework expectations and give their view on any regulatory issues, all of which will help your device stay on the market and generate sales for longer.

Meridian Medical is an established and experienced contract medical equipment manufacturer specialising in a wide range of medical device design, development and supply services.

To find out more about how Meridian Medical can help you with your medical product design and manufacture, get in touch today by filling out our online form or contacting us on 01903 732344 or info@meridian-medical.com.

Author: Paul Kearsley,

Technical Manager, Meridian Medical

Paul Kearsley brings a lifetime of engineering expertise to his role as Technical Manager at Meridian Medical. With an HNC in Mechanical Engineering and a foundation built during a four-year engineering apprenticeship, Paul has spent over 40 years running his own design company. Over the decades, he has designed more than 1,000 consumer, industrial, and medical devices, showcasing his ability to deliver innovative solutions across a broad spectrum of industries.

A pioneer in the transition from traditional drafting techniques to modern CAD workflows, Paul began his career on the drawing board, adopted AutoCAD 2D early on, and embraced 3D modelling with SolidWorks in 1997. His vast experience and technical leadership play a key role in Meridian Medical’s commitment to producing high-quality, single-use medical devices.